CNC machines such as CNC punch or laser machines are significant investments for any manufacturing...

Heat avoidance: Cutting through thick plate material with precision

Cutting thick plate material presents a unique set of challenges, not least among them is the problematic heat build-up that can hinder precision and efficiency. It is within this context that JETCAM Expert's nesting software and its 'Heat Avoidance' feature become particularly useful. This blog probes the problems caused by heat accumulation during cutting operations, understand what a heat avoidance algorithm does, and explain how it addresses these issues.

The Problems Caused by Heat Build Up

Heat build-up during the cutting process can lead to multiple negative repercussions, such as material deformation, distortion of the workpiece, and overall degradation in edge quality of the part. Significant heat can hinder overall efficiency within the cutting operation, as programmers may have to manually modify the cutting sequence in order to maintain part quality. This can also lead to delays, waste and additional operational costs, which either force price increases or eat into your margin.

The Importance of a Heat Avoidance Algorithm

The introduction of a heat avoidance algorithm into nesting software is not just beneficial—it's essential. A heat avoidance algorithm holds the capacity to stem the tide of problems that heat build-up brings, consequently nurturing improved cutting performance. By incorporating this kind of intelligent functionality, manufacturers can mitigate damage and ensure their operations fulfil their accuracy requirements.

Understanding the Heat Avoidance Algorithm in JETCAM Expert

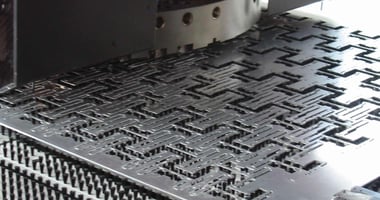

JETCAM Expert's nesting software embeds a sophisticated Heat Avoidance algorithm tailored to combat the issues discussed above. The algorithm examines the cutting path, material thickness, and other crucial parameters, to define the best strategies for cutting. It does this by creating a series of heat ‘zones’, as the laser continues to work within specific areas of the sheet. We can specify criteria such as the distance from the area being cut to be considered within a heat affected zone, the cooling rate that each contour will cool, and corner tolerance. Lead in position and contour direction options can also be specified, giving maximum flexibility.

Benefits of Utilising Heat Avoidance

Implementing Heat Avoidance in JETCAM Expert delivers a series of benefits. Firstly, it will significantly reduce programming time, as the programmer will no longer have to examine the cutting sequence in order to determine where potential heat build-ups might occur. The heat avoidance algorithm will run as a part of the sequencing operation, taking just a few seconds longer. Overall part quality will be improved, and, while the cutting sequence will be longer than the shortest order of cutting possible, it will mean that you are not scrapping and remaking parts – a process that costs time, machine availability and material.

Conclusion:

Managing heat accumulation is a ‘necessary evil’ when cutting of thick plate material on CNC plasma machines or similar technologies. The effectiveness of JETCAM Expert's Heat Avoidance feature helps to automatically mitigate these challenges while bolstering productivity and precision. It’s available in all versions of JETCAM Expert, and can be configured in a matter of minutes.

%20(Custom).jpg?width=1000&height=252&name=JETCAM%20logo%20(glossy%20effect)%20(Custom).jpg)