Defects in pre-preg composite material are commonplace, yet many manufacturers waste significant...

Navigating problems of manufacturing with Pre-Preg Composite Materials

A Challenge in Location, Life, and Consumption Tracking

Pre-preg composite materials offer unparalleled strength-to-weight ratios and performance characteristics. However, working with these materials presents a unique set of challenges that can significantly impact production efficiency and material waste. This blog post delves into the complexities of managing pre-preg composites, focusing on location tracking, life management, and consumption monitoring.

Tracking raw materials in/out of the freezer is a challenge that is multiplied when the material is cut into plies and kitted. You then need to track the location and life of every single ply.

Storage and Handling of composite materials

One of the primary challenges when working with pre-preg composites is their storage requirements. These materials must be kept in freezers until use, typically at temperatures around -18°C (0°F). This necessity stems from the partially cured nature of the resin in pre-pregs, which can continue to cure slowly even at room temperature.

Tracking Composite Material Usability

Once removed from the freezer, the clock starts ticking on the material's usability:

- Room Temperature Life: Pre-pregs have a limited life at room temperature, typically ranging from 7 to 30 days, depending on the specific material.

- Defrost Time: The time it takes for the material to defrost must be carefully monitored and factored into the overall out-time.

- Cumulative Tracking: Any time spent out of the freezer, even if later returned, must be cumulatively tracked to ensure the material has not exceeded its room temperature life.

- Handling life tracking: Although a material may have 20-30 hours left before its expiry, it can often already be too stiff to work with, resulting in it being scrapped. Therefore, mechanisms need to be in place to ensure that it reaches layup before this occurs.

Dealing with composite material defects

Pre-preg materials are prone to various defects that can compromise either the visual or structural quality of the final product. According to a study published in the Journal of Composite Materials, defect rates in pre-preg composites can range from 5% to 15%, depending on handling practices and environmental controls.

Common pre-preg composite defects include:

- Voids and porosity (accounting for approximately 40% of defects)

- Fibre misalignment (approximately 25% of defects)

- Resin-rich or resin-starved areas (about 20% of defects)

- FOD - Foreign object debris (approximately 10% of defects)

- Other issues such as ply drops and bridging defects that occur during layup (about 5% of defects)

These statistics underscore the importance of rigorous quality control measures throughout the manufacturing process.

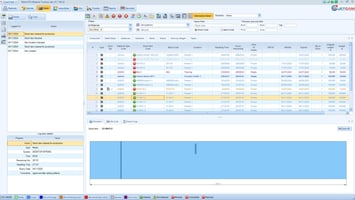

CrossTrack allows the creation of unlimited defects, with the option to then nest around them

The Complexity of Kitting

When pre-preg materials are cut and 'kitted', grouping the plies for the layup process, a new layer of complexity emerges:

- Individual Ply Tracking: Each ply must be tracked separately, as they may come from different rolls with varying remaining life spans.

- Scrap and Replacement: If a ply is scrapped and replaced with material from a different batch with less remaining life, it affects the overall life of the entire kit.

- Life Synchronisation: The kit's usable life becomes determined by the ply with the shortest remaining life, requiring careful management to minimise waste.

Although outside the scope of this blog, another factor to consider is nesting – the most efficient dynamic nest will take significantly longer to unload and kit at the cutter, with the additional time taken offsetting the material savings. The solution for this is hybrid progressive nesting, which groups kits together but allows plies to be nested a fixed distance back into the nest. This provides a balance between an efficient nest and ease of unloading on the shop floor, and is ideal when used in conjunction with automated sorting solutions, such those offered by Airborne.

Although outside the scope of this blog, another factor to consider is nesting – the most efficient dynamic nest will take significantly longer to unload and kit at the cutter, with the additional time taken offsetting the material savings. The solution for this is hybrid progressive nesting, which groups kits together but allows plies to be nested a fixed distance back into the nest. This provides a balance between an efficient nest and ease of unloading on the shop floor, and is ideal when used in conjunction with automated sorting solutions, such those offered by Airborne.

ERP Systems: A Square Peg in a Round Hole

Many Enterprise Resource Planning (ERP) systems are ill-equipped to handle the unique tracking requirements of pre-preg composites:

- Roll Tracking Limitations: Some ERP systems cannot track individual rolls, instead logging 'batch length', which is insufficient for tracking roll length, location and life.

- Multi-Layer Cutting: Some manufacturers cut multiple layers of material simultaneously, a practice that many ERPs cannot accurately track or account for in inventory management. Nor can they correctly track the resulting single ply entities that comprise of multiple layers.

- Life Cycle Management: Standard ERP systems typically lack the capability to track the complex life cycles of pre-preg materials, in and out of the freezer, cutting to individual plies, which themselves then need to be tracked through each manufacturing stage to the final part.

A Solution to the composite conundrum: JETCAM's CrossTrack composite manufacturing software

JETCAM's CrossTrack composite manufacturing software is designed to bridge the gap between traditional ERP systems and the unique requirements of pre-preg composite management:

- Seamless ERP Integration: CrossTrack connects with existing ERP systems to provide a comprehensive view of material inventory and lifecycle.

- Granular Tracking: The software enables tracking of individual rolls, plies, and kits throughout the manufacturing process.

- Life Management: CrossTrack automates the tracking of material life, including freezer time, out-time, and defrost periods – both raw roll materials and of cut plies as they move through production.

- Multi-Layer Cutting Support: The system can accurately account for multi-layer cutting processes, ensuring precise inventory management.

- Quality Control: By providing real-time visibility into material status and history, also logging defects, CrossTrack eradicates the risk of using expired or compromised materials.

- Traceability: The ability to create a full traceability report for the finished composite part, detailing every transaction that occurred against every piece of material, including material life information at the point of curing.

Summary

While pre-preg composites offer exceptional performance benefits, their management presents significant challenges. ERP alone generally cannot solve them, but by integrating and using CrossTrack to deal with the unique issues that working with composites presents, companies can not only streamline the manufacturing process but also, as a byproduct, deliver full traceability. For industries such as aerospace and automotive this is essential.

%20(Custom).jpg?width=1000&height=252&name=JETCAM%20logo%20(glossy%20effect)%20(Custom).jpg)