Find out more about CrossTrack

CrossTrack is designed to complement your ERP or MES system, providing additional functionality and traceability required by composite manufacturers, and also elegantly handling real-world scenarios such as scrapping and cutting plies by hand, nesting across multiple rolls, or nesting on multiple layers of material.

Complete this form to find out more about what CrossTrack can do for your business, and find out about our free nesting benchmark comparison.

ROI measured in months or weeks, not years.

Nesting software can often pay for itself in a considerably shorter time than any other hardware or software purchase. If you are spending a seven-figure sum per year on material, even a 1% saving is a five-figure sum. Most of our customers will see an ROI of under 12 months, with many calculating that the software paid for itself within weeks.

Tight integration with ERP/MES.

The most important requirement of any shop floor system is its ability to communicate with existing enterprise manufacturing software. CrossTrack provides multiple methods of bi-directional communication, not only with ERP/MES, but also with shop floor CNC equipment such as CNC cutters, kitting robots or automated material handling systems.

Key features in under 60 seconds

Dealing with real-world situations

Re-nesting scrapped plies at the cutter

With CrossTrack's Shop Floor Station, operators have a clean interface that shows the schedule of cutting.

Once a nest is cut, they can mark plies as cut or not done, and then instantly reschedule them for nesting, with NC code for a new nest available in minutes.

KEY BENEFITS

Fast ROI

When integrated with JETCAM's ultra performance nesting, CrossTrack can often pay for itself in months or even weeks in material savings alone.

Shop floor interface

Easily transfer raw materials, layup tools, containers or kits between locations using PCs or mobile devices for complete hands-off logging.

Fast installation

With full video tutorials covering both installation and usage, the learning curve is short. Watch the videos on PCs, tablets or even a mobile device.

Traceability

Either drill down on screen or generate a PDF on a kit, roll, tape or entire batch. You can also write your own custom reports to output instantly or automatically to Excel.

Easy ERP integration

Various data exchange methods, allowing you to easily get data in/out of the system and providing tight integration with existing systems.

Real-world solution

Whether you need to hand cut a ply or want to nest over two rolls, CrossTrack is designed to handle the real-world scenarios that composite manufacturers have to deal with.

Roll/kit life tracking

Know both the location and life of yourraw materials, and once they're cut track your kits to ply level until they are out of the autoclave.

Custom data

Create custom data fields across CrossTrack that are then displayed like native columns. Errors are reduced as staff input less data, with defaults suggested to minimize errors.

Award-winning software

Trusted by our customers, respected by our peers.

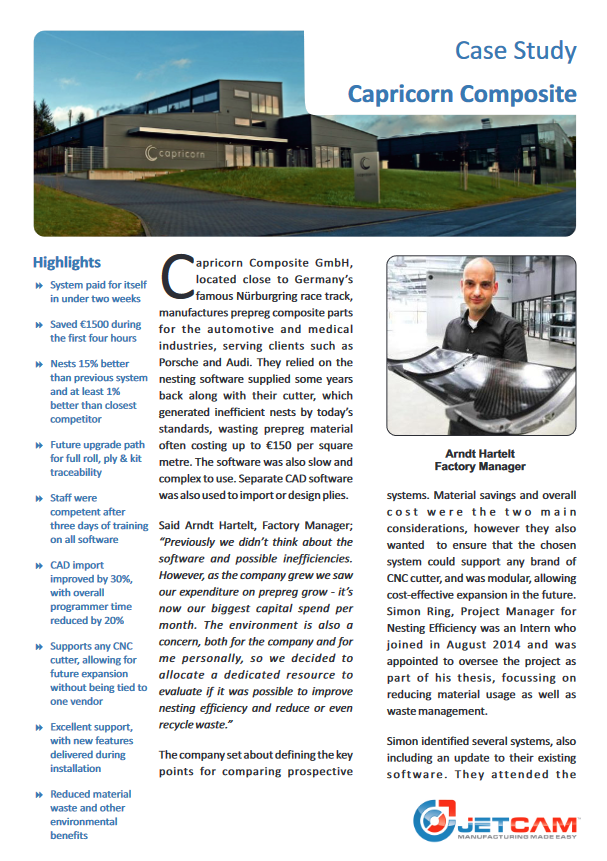

Case Study: Capricorn Composites

€1500 saving in 4 hours

Capricorn Composites requested a nesting benchmark at a trade show. Within 10 minutes we demonstrated a 14% material saving.

The software was purchased and installed the following month. The company saw an ROI on their investment within two weeks, with €1500 being saved while JETCAM engineers were on-site training the staff on how to use the software!

© JETCAM International s.a.rl.