How much would just 1% material saving mean to your business?

Software that delivers an ROI measured in months or weeks, not years.

What is a nesting benchmark comparison?

Send us your best nest along with its associated DXF plies and we will run it through our High and Ultra Performance nesting engines for comparison. We'll then provide you with the DXF nest output so you can see the difference.

ROI measured in months or weeks, not years.

Nesting software can often pay for itself in a considerably shorter time than any other hardware or software purchase. If you are spending a seven-figure sum per year on material, even a 1% saving is a five-figure sum. Most of our customers will see an ROI of under 12 months, with many calculating that the software paid for itself within weeks.

Request your free nesting benchmark comparison

The process

Here's what we need in order for you to compare our nester with your existing software.

1. CAD Files

Provide us with a DXF of your most efficient nest, along with the associated CAD files. Alternatively, we can easily split a DXF nest.

2. Limitations & Spend

Tell us the material borders, spacing between plies, allowed orientation and any rotational tolerance allowed, along with your annual material spend.

3. NDA (optional)

As many of our customers work in aerospace or defence, we are happy to sign your NDA before receiving files.

What else can JETCAM do?

Although JETCAM has been developing nesting software since 1986, our reach extend much further into manufacturing, solving problems that ERP system often cannot, including:

- Nest scheduling by the cutter

- Material location, life and consumption tracking and management

- Life track of both material and kits (to ply level)

- Automatic allocation of material during nesting ('dynamic' nesting)

When we contact you to arrange the nesting benchmark, we can also arrange a demonstration tailored to your specific requirements.

KEY FEATURES

Fast ROI

When integrated with JETCAM's ultra performance nesting, CrossTrack can often pay for itself in months or even weeks in material savings alone.

Shop floor interface

Easily transfer raw materials, layup tools or kits between locations using PCs or mobile devices for complete hands-off logging.

Fast installation

With full video tutorials covering both installation and usage, the learning curve is short. Watch the videos on PCs, tablets or even a mobile device.

Traceability

Either drill down on screen or generate a PDF on a kit, roll, tape or entire batch. You can also write your own custom reports to output instantly or regularly automatically to Excel.

Easy ERP integration

Various data exchange methods, allowing you to easily get data in/out of the system and providing tight integration with existing systems.

Real-world solution

Whether you need to hand cut a ply or want to nest over two rolls, CrossTrack is designed to handle the real-world scenarios that composite manufacturers have to deal with.

Roll/kit life tracking

Know both the location and life of yourraw materials, and once they're cut track your kits to ply level until they are out of the autoclave.

Custom data

Create custom data fields across CrossTrack that are then displayed like native columns. Errors are reduced as staff input less data, with defaults suggested to minimize errors.

Supported machines

Including (but not limited to):

- AGFM

- Blackman & White

- DXF output

- Eastman

- Exact

- Gerber

- Graphtec

- Lectra

- Zund

Award-winning software

Trusted by our customers, respected by our peers.

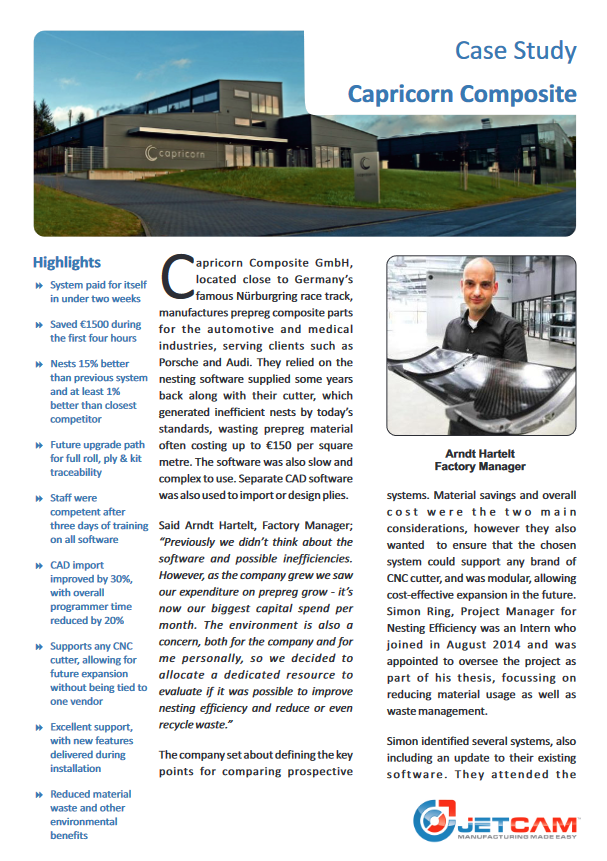

Case Study: Capricorn Composites

€1500 saving in 4 hours

Capricorn Composites requested a nesting benchmark at a trade show. Within 10 minutes we demonstrated a 14% material saving.

The software was purchased and installed the following month. The company saw an ROI on their investment within two weeks, with €1500 being saved while JETCAM engineers were on-site training the staff on how to use the software!

© JETCAM International s.a.r.l.