CNC machines such as CNC punch or laser machines are significant investments for any manufacturing...

Six ways to calculate the Return on Investment of Software

A question often posed to us is the financial justification of a quoted nesting or software automation solution. When compared to, say, purchasing a new machine with known specifications, investing in intangible assets such as software can seem harder to justify. However, it needn’t be that complex to be able to associate financial values to the savings that can potentially be made. Here are six common areas that you can consider.

Material efficiency

One of the primary benefits of advanced nesting software is its capability to maximise material utilisation. In both the sheet metal and composite markets that we serve, our sophisticated algorithms minimise waste by fitting more parts into a single sheet or roll, also factoring the effective use of remnant materials or those with expiry dates, such as pre-preg composites. By tracking offcuts and remnants, the system ensures they are consumed before new materials are cut into, leading to substantial savings.

However, gaining the maximum material saving can have a negative impact on the shop floor, especially when cutting roll-based materials on conveyorized cutters, where nests can be many metres in length. If several ‘kits’ (groups of components) are nested, the operator needs to sort these at the end of cutting. A fully dynamic nest will take much longer to sort, so any savings made on material are lost on extra staff time. A way to mitigate against this is by using different nesting strategies such as Progressive Nesting or Hybrid Progressive nesting, which sends each kit one by one to the nesting engine, ensuring a balance between material efficiency and ease of unloading and sorting after cutting. Other factors, such as nesting around material defects, can also provide further savings.

Calculating the saving: A nesting benchmark comparison is the easiest way to calculate your ROI. One company walked onto our booth at a trade show with a USB stick full of DXFs. Within 10 minutes we had run them through our nester and beat their best nest by 15%. Look at your annual spend on nested materials and this will give you a per-percentage saving that you can use against any nesting benchmark results.

Material life

In industries such as composite manufacturing, pre-preg material needs to be kept in a freezer and defrosted before use. With a life span at room temperature of only a few hundred hours for material that can cost upwards of $100 per square metre, maximising its usage is extremely important. By tracking location, life, ‘out time’ and consumption of materials, and by automatically allocating the soonest to expire material when a nest is created, this ensures that material is used in a timely and efficient manner.

Calculating the saving: If your business tracks material lost through life expiration, then this value can be added to your ROI saving. A customer using CrossTrack MTL saw an ROI of under two months, as they were tracking several hundred rolls on-site and would lose one every one-two months because of previous poor processes.

Tracking expensive pre-preg material in and out of the freezer can deliver significant savings

Optimising Machine Runtime

Nesting software goes beyond merely improving material use. It can enhance machine runtime by generating optimised NC (Numerical Control) code that ensures machines operate at peak efficiency, potentially even improving the machine’s life. By providing faster cutting sequences, smoother machine operations and reducing idle times, the cumulative savings from decreased machine wear and increased throughput should not be underestimated.

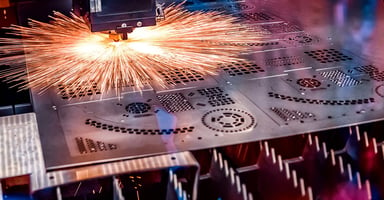

Calculating the saving: This is more difficult to quantify, as some manufacturing processes will have more opportunities for improvement. For example, one laser customer replaced their OEM software for a new fibre laser with JETCAM Expert, and used JET-Cut Fly Cutting. This automatically examines the part for arrays of holes (such as air vents) – instead of cutting each hole individually, the laser head will pass over the horizontal cuts, turning the laser on and off, and then place a radius on the turn rather than having to halt to change direction. Afterwards, it will complete the vertical cuts. This, along with other optimisations helped the customer realise a 13.2% improvement of throughput on their laser per month.

Fly cutting can dramatically reduce the cutting time of complex arrays such as this

Reduction in Staff Time and Simplification of Processes

Automation software streamlines processes, reducing the manual input required from staff. The reduction in staff time - from the CAD drawing, through to NC code for the machine and then onto automation on the shop floor all translate directly into cost savings, allowing skilled employees to focus on higher-value tasks. Furthermore, this simplification leads to a reduction in the potential for human error and requires less ongoing training, improving overall quality and consistency.

While JETCAM Expert provides both interactive and automatic tools for creating nests, additional products such as JETCAM Orders Controller and CrossTrack de-skill these processes significantly, reducing the workflow process to a few clicks of the mouse, where staff can make more informed decisions rather than having to worry about technical details.

Calculating the saving: Examine your current processes in relation to the software product you are intending to replace them with. Then, see if a comparison can be made for each step in that process.

Integration with ERP or other data systems

Automation and nesting software's ability to integrate with existing Enterprise Resource Planning (ERP) and other data systems can deliver significant savings. It allows real-time data flow between sales, inventory, and production, enhancing decision-making and responsiveness to market demands. This integration allows for accurate cost estimates and more precise delivery times, both of which are invaluable to customer satisfaction and retention. It also aids purchasing, as live material consumption data ensures they are working with the most up-to-date information before making a purchasing decision.

Keeping ERP or other systems updated is often a manual process, meaning that staff are performing manual double entry of data, which itself is open to error. This can also cause issues with traceability – a significant factor for companies serving industries such as aerospace or defence.

Calculating the saving: Identify areas where data is currently manually maintained and/or entered into ERP and associate times against it. One customer in the composite industry already had ERP integration with their Autoclave on the shop floor. They implemented CrossTrack for Composites and plan to set the Autoclave software to change the location status of composite parts when they finished curing, removing the requirement of staff to scan a barcode for each item after it left the autoclave.

Standardising on one system

For companies that have multiple machine brands and cutting technologies, having just one nesting system can have several benefits. While the initial purchase will need to include support for each machine (usually through postprocessors and additional configuration), you are likely to save significantly on software maintenance, support and upgrade costs, as you will no longer be paying several vendors. Often, companies with systems in place that support specific machines end up having ‘experts’ on one that have no knowledge on the others. When it comes to holidays, sickness or the person leaving the business, additional costs are incurred to train new staff. Having a single system spreads the risk, ensuring that all relevant staff can drive all machines.

JETCAM also assist with customer learning by providing free access to its online ‘University’ video library, consisting of hundreds of tutorial videos on all products that are available 24/7. Integrated Google Translate ensures that the narrative is available in all common languages.

Calculating the saving: Add up your annual costs for existing systems and compare to the proposed system. Also consider how frequently you may have had to pay for training of new staff on one or more system.

Putting the figures together

By now, you should have a good understanding of where a new solution will deliver benefits. Now, it's simply a case of adding them up and comparing them against the cost of the replacement system. Most of your calculated savings can be linked to time, e.g. saving approximately A per month on materials, B per month reduction in staff time, C per month increased machine throughput, D time reduction due to ERP implementation, E saving on consolidating maintenance, etc.

Imagine that a system was costing 50,000. You've calculated the above areas for savings and come up with an estimate for 75,000 per year. That's a saving of 6,250 per month, which neatly works out at a complete return on investment of 8 months. After that, it's all pure profit on the bottom line.

We've put together a simple Nesting Savings Calculator on our website that will help you put numbers to three of the figures above - material efficiency, programming time and machine runtime. Even if you don't have numbers against all three, it will help you to visualise the potential savings on offer. Simply use the sliders on the left to select the current values and potential percentage saving, then click Calculate My Savings. You'll immediately see your approximate annual saving for each key area, along with a total underneath. Hover over the Info icons to see how these numbers were calculated.

Visit the Nest Savings Calculator here.

The JETCAM Nesting Savings Calculator provides material, manpower and machine estimates

Summary

We’ve listed six areas here where it should be relatively simple to place a financial value against them. It may be that some of the figures will be more approximate than others for your business, but still be accurate enough to give you a good business case. Material savings alone are often enough to provide solid justification but when combined with multiple other savings it becomes not a question of ‘should you’ but of ‘why wouldn’t you?’

Start the ball rolling today with either a nesting benchmark comparison or an online discussion to identify potential areas for improvement in your nesting and automation processes.

%20(Custom).jpg?width=1000&height=252&name=JETCAM%20logo%20(glossy%20effect)%20(Custom).jpg)