Efficiency and traceability have continuously been core tenets in automated manufacturing, forcing...

Streamlining Manufacturing Processes with CrossTrack Integration

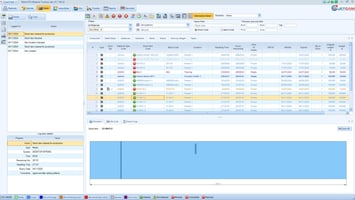

In the ever-evolving landscape of manufacturing technology, efficiency and cost reduction are at the forefront of strategic business goals. Integrating products, such as CrossTrack, into your manufacturing processes can deliver substantial time and cost benefits by bridging the gap between your ERP/MES system and nesting software. In this article, we will explore how CrossTrack can be integrated with material storage, material loading, material unloading, and part sorting systems, delivering optimised workflows, reducing waste, and increased efficiency and traceability.

Material Storage

One of the primary challenges in the manufacturing sector is real-time management and monitoring of materials within the storage facilities. CrossTrack goes beyond the boundaries of conventional material inventory tracking by providing complete traceability of sheet metal and composite materials throughout their life cycle. The integration of CrossTrack with your storage systems delivers benefits such as:

- Automated material tracking: Real-time visibility of material locations and quantities, reducing the time spent on manual inventory checks. This can either be fully tracked by CrossTrack, or it can receive information directly from your material storage system.

- Optimised space utilisation: Intelligent allocation of materials within the storage system, maximising the efficiency of the available space.

- Enhanced accuracy: Minimising errors caused by manual data entry, ensuring accurate inventory data for informed decision-making and faster delivery to the CNCs when required.

Material Loading

Manual material loading can become a bottleneck in the production process, leading to increased overall job runtime and labour costs. Combining CrossTrack with your material loading systems offers a streamlined solution for loading materials onto the cutting machines. Critical benefits of this integration include:

- Automated scheduling: CrossTrack's nesting software can coordinate with the loading systems to provide information on what material is needed and by when.

- Reduced lead times: By automating material loading processes, CrossTrack helps minimise delays and improve overall throughput. No time is wasted by operators handling the wrong material.

Part Unloading

CrossTrack not only ensures efficient material loading but also excels in the process of unloading of cut parts. By integrating with this part of the production chain, manufacturers can experience greater efficiency in removing cut parts from the cutting machine before sorting and preparing them for further processing. Key advantages include:

- Minimised machine idle time: By automating part and sheet skeleton removal from the machine bed, CrossTrack significantly reduces downtime and frees up the cutting machine for additional tasks, providing greater overall throughput.

- Remnant material management: CrossTrack's intelligent tracking system accurately records the quantity and location of offcut remnant materials, enabling manufacturers to make better use of these in future production.

- Reduced labour expenses: Automation of the unloading process reduces the need for manual intervention, leading to lower labour costs and a more efficient workforce.

Part Sorting

Accuracy and speed in the part sorting process are critical to maintain a streamlined production schedule. CrossTrack's integration with part sorting systems streamlines this process by providing:

- Automated part identification: CrossTrack's system knows the location of every part on the nest, which it can then provide to the unloading/sorting system.

- Improved traceability: CrossTrack's comprehensive tracking system helps maintain full traceability of parts from the initial nesting process to the shipment of the final product.

- Balancing nesting efficiency with faster unloading: Features such as JETCAM's progressive nesting allow nests to be created that will be much faster to sort, as less buffering will need to occur. Buffering takes place when parts must be stacked in a specific order, but later parts are cut first (for better material efficiency) and need to be placed in a buffer area while other parts are cut, unloaded and sorted into order.

In conclusion, integrating CrossTrack with your material storage, loading, unloading, and part sorting systems not only improves overall efficiency but also delivers considerable cost savings for your manufacturing operations. With its intelligent automation and comprehensive traceability features, CrossTrack positions itself as a trusted partner and a valuable addition to your manufacturing technology stack.

%20(Custom).jpg?width=1000&height=252&name=JETCAM%20logo%20(glossy%20effect)%20(Custom).jpg)