In the ever-evolving landscape of manufacturing technology, efficiency and cost reduction are at...

Integrating Sheet Metal Nesting Software with an ERP System: Unlocking Efficiency and Saving Time

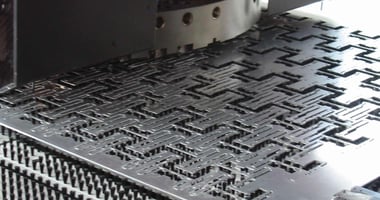

In sheet metal fabrication, time and efficiency play a key role in being able to maintain competitiveness and effectiveness. If you are looking to streamline your production and workflow processes, starting at the beginning of the process is the most logical place to begin. Such integration brings together two powerful tools which can mutually enhance their functionality, bringing forth immense benefits to a manufacturing business.

Inventory Management

Integrating nesting and shop floor automation software with an ERP system provides real-time inventory stock data. Live material stock, sheet usage, offcuts (remnants), and material scrap are all tracked and updated in the ERP. This accurate data allows for smarter decision-making by your purchasing department, minimising overstocking, material waste, and, as a result, capital expenditure . It also allows you to run Just In Time for material delivery, to align with with production schedules.

Improved Workflow

Creating nests can be a rather disjointed process, but by linking ERP to systems such as CrossTrack, which in turn uses JETCAM Expert as a 'black box' to generate nests, you can simplify and streamline the process. ERP can simply pass a list of parts or assemblies for manufacture, with CrossTrack then allowing a mixed order list to be generated. The programmer can then sent this mixed order list for nesting, allowing for the absolute best material efficiency. At the point of sending the items for nesting, CrossTrack will select and allocate the best material stock to use, and then create one or more nests. Furthermore, it will schedule the nests for cutting, and also mark the required material for transfer. This allows for comprehensive and accurate work scheduling, reducing setup times and increases overall workflow speed.

Data Accuracy and Consistency

Transfer errors between systems can disrupt an entire production flow, especially when data has to be entered multiple times manually. By either linking the two systems or, at the very minimum, importing electronic data rather than manually inputting it, inconsistency issues are significantly reduced as there is a single source of information. This drastically decreases the likelihood of errors while increasing the ease of tracing problems when they do occur.

Increased Speed of Order Processing

By automating the CAD import and nesting process, companies can go from receiving an order to starting to run the job on a CNC machine extremely quickly. These 'de-skilled' processes allow companies to move away from relying on highly skilled programmers. This problem can be exacerbated when a company has multiple CAM/nesting systems, with some staff only proficient in one but not others.

Case studies

- A company manufacturing switchgear in the US replaced several nesting systems driving multiple technologies and machine brands with JETCAM Expert. Programming time was reduced by 75%, nests were up to 14% more efficient, and one programmer was freed up by 95%, allowing him to be more productive in other areas of the business. They also integrated it with Aquila DMM software.

- A German manufacturer of fire doors and switchgear cabinets selected JETCAM Expert due to its parametric programming capabilities, allowing complex parts or assemblies to be created and tooled, based on inputting key variables. They integrated it with their in-house Oracle based ERP system, allowing parts to be created, tooled and nested fully automatically.

- A US manufacturer of fireplaces evaluated JETCAM Expert against several other system. The key aim was to integrate with their MRP and Pro-E CAD system. JETCAM was selected and delivered an ROI in just 10 months. This was achieved to nest being up to 10% more efficient, programming time being reduced by 2 hours a day, improved machine cycle time and integration with a part picker, which automatically unloaded punched parts.

Detailed Performance Metrics

As data begins to flow and collect within systems such as CrossTrack, this can provide visibility over and above what ERP can traditionally provide. For example, capturing actual versus estimated runtime allows you to confirm the accuracy of your quotes and margins. Correctly allocating material, also taking either scrap or parts nested within other parts into account ensures that you can remain competitive. These insights are invaluable for continuous process improvement and strategic planning.

Summing up

The integration of nesting and automation software with ERP is a strategic decision that can propel a manufacturing unit towards significantly better time and efficiency metrics. This integration offers not only a means to enhance performance but can also provide a competitive advantage in an ever-demanding market.

%20(Custom).jpg?width=1000&height=252&name=JETCAM%20logo%20(glossy%20effect)%20(Custom).jpg)

.png?height=200&name=640px-Telex_Ticker_Tape_(11438441186).png)